Museum of Glass and Jewellery in Jablonec nad Nisou

Glass beads

Transcript

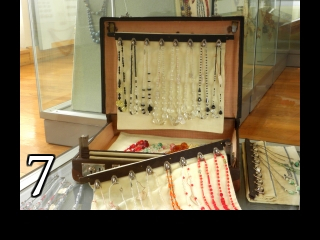

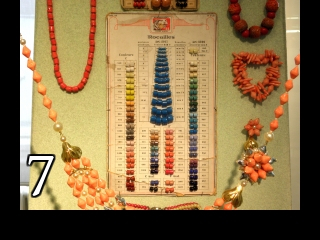

Glass beads were originally responsible for the world fame of Jablonec. They are still produced here using various technologies in an incredible variety of shapes, colours and sizes. Depending on the production process we speak of pressed, cut, wound, blown, waxed, sintered and tiny beads. All these types were most important for the Jablonec costume jewellery industry. Thanks to local traders, they were exported as early as the 19th century in unbelievable quantities all over the whole world. Today the tiny glass beads are in the greatest demand. Trading in Jablonec costume jewellery was not a monopoly of big export houses, most of them with their headquarters in Jablonec nad Nisou. This cardboard briefcase with samples of glass necklaces belonged to a small manufacturer and merchant called Václav Hejna from Prosíčko u Vrátu, who set up his business in 1927. He made wound beads and figurines, but he also bought cut beads and then assembled them into pieces of costume jewellery. Sintered costume jewellery was made by pressing glass powder into the required form, and then firing it to achieve its sintering into a compact mass. The technology of sinter production is fundamentally the same as the production of ceramics. The main component was from the very beginning frit or fritted glass – crushed feldspar glass, i.e. the material which forms the chief component of Sèvres porcelain. Combinations and the addition of various materials to the basic frit yield effects that cannot be achieved in glass by any other method. In the Jizera Mountains the company Gebrüder Redlhammer was the first to launch the industrial production of ‘glass-porcelain’ beads and buttons. In the second half of the 20th century, this production line was taken up by Preciosa, which also made sintered mosaic stones used on façades.